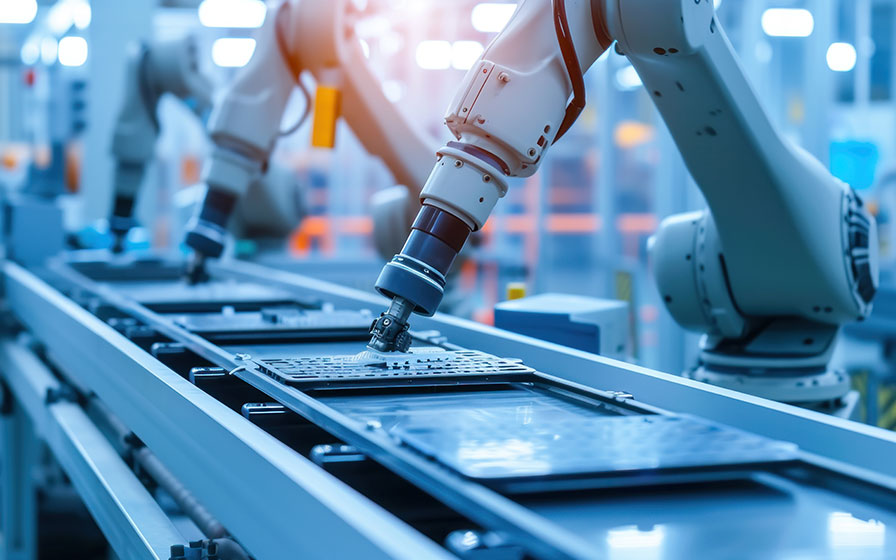

Automation is leading the charge in revolutionizing the medical manufacturing industry, transforming how healthcare OEM’s operate by enhancing precision, safety, and efficiency. As the demand for accurate and timely handling of medical materials increases, automated systems have become essential for delivering dependable results. Among these systems, automated material handling stands as a critical component, driving the streamlining of operations. At the heart of this innovation are servo motors, which offer the reliability, speed, and precision needed to elevate medical automation and meet the stringent demands of healthcare environments.

The Growing Importance of Automated Material Handling for Medical Machine OEMs

Medical machine OEMs face unique challenges in developing equipment that meets the exacting standards of modern healthcare environments. Precision, sterility, and adherence to stringent safety regulations are critical when handling delicate instruments, transporting pharmaceutical products, or managing high-throughput laboratory tasks. As the demand for flawless material handling grows, OEMs must deliver solutions that ensure reliability and efficiency.

Once widely used, manual processes are increasingly seen as inadequate due to their susceptibility to human error, inefficiencies, and inconsistencies. These can jeopardize patient safety and disrupt medical operations. Automated material handling systems offer a superior alternative by minimizing errors, increasing throughput, and enhancing overall operational safety.

Once widely used, manual processes are increasingly seen as inadequate due to their susceptibility to human error, inefficiencies, and inconsistencies. These can jeopardize patient safety and disrupt medical operations. Automated material handling systems offer a superior alternative by minimizing errors, increasing throughput, and enhancing overall operational safety.

At the heart of these systems are servo motors, which provide the control, speed, and precision that medical applications demand. Servo motors offer the accuracy required to handle sensitive medical materials with care, ensuring that medical equipment operates seamlessly and meets the high standards set by regulatory bodies. By integrating these advanced motors into their machines, OEMs can help healthcare providers achieve new operational efficiency and compliance levels.

How Servo Motors Drive Medical Automation

Servo motors are central to the success of automated material handling systems in medical environments. They offer:

- Superior Precision: Medical tasks, from robotic surgery to laboratory sample handling, require extreme precision, which servo motors can achieve by finely controlling motion.

- Reliability Under Pressure: In an industry where system failures can have serious consequences, servo motors are known for their reliability and consistent performance, making them an ideal choice for critical medical applications.

- Customizability for Various Applications: Servo motors can be customized to fit a range of medical automation processes, from automated pharmacy systems that manage medication inventory with pinpoint accuracy to robotic surgical tools that require micro-movements.

By incorporating servo motors into automated systems, OEMs can help medical facilities reduce the need for human intervention, thus lowering the risk of contamination, ensuring sterility, and boosting the overall safety of medical processes. These motors also enable faster, smoother, and safer operations in applications such as automated dispensing machines, lab automation, and robot-assisted procedures, further advancing the adoption of cutting-edge medical automation technologies.

Propelling the Future of Medical Automation

Integrating automated material handling systems, particularly those powered by advanced servo motors, is transforming the future of medical machine OEMs. These systems have the potential to revolutionize everyday tasks, from enhancing the precision of robotic surgery to automating pharmaceutical workflows.

Integrating automated material handling systems, particularly those powered by advanced servo motors, is transforming the future of medical machine OEMs. These systems have the potential to revolutionize everyday tasks, from enhancing the precision of robotic surgery to automating pharmaceutical workflows.

As servo motor technology continues to evolve, its role in driving medical automation will expand, offering new possibilities for automating even the most complex and high-stakes tasks in the healthcare industry. OEMs that adopt these technologies will be well-positioned to lead the way in providing solutions that meet the healthcare sector’s ever-growing demands for precision, safety, and efficiency.