In today’s fast-paced beverage industry, precision, speed, and seal integrity are critical for ensuring high-quality stand-up pouch packaging. Consumers demand portable, durable, and leak-proof beverage packaging. Manufacturers must depend on their equipment to guarantee consistent quality, high efficiency, and minimal waste.

The Growing Demand for Stand-Up Pouch Packaging in Beverages

Stand-up pouches are quickly becoming the go-to packaging solution in the beverage sector due to their lightweight structure, visual appeal, and cost-efficiency. While the format is convenient for consumers, it raises the bar for manufacturers who must maintain exacting standards in seal integrity and fill accuracy. To maintain product integrity and throughput, OEMs and equipment manufacturers must overcome several challenges.

To meet performance goals and avoid costly packaging failures, pouching systems must deliver:

- High-Speed Processing – In pursuit of faster cycle times, some systems risk inconsistent pouch placement or misaligned components. High-performance motion systems mitigate this trade-off by synchronizing multi-axis movements with precise timing, ensuring smooth transitions between filling, sealing, and labeling

- Reliable Seal Quality – Even minor imperfections in a pouch’s seal can compromise product quality. Variables like heat dwell time, sealing pressure, and material compatibility must be carefully managed to ensure durable, tamper-resistant seals that hold up throughout distribution.

- Precision Filling and Labeling – Maintaining exact product volume and consistent label placement to protect brand reputation and reduce waste .

- Maintaining Uniform Pouch Dimensions – Inconsistencies in pouch sizing impact not only product volume but also shelf presentation. Consistent registration, cutting, and sealing help ensure each pouch matches specifications and meets consumer expectations.

By upgrading to intelligent motion systems, beverage producers can leverage real-time monitoring and diagnostics, reducing manual handling, improving uptime, and managing costs.

Addressing Real-World Packaging Demands with Smarter Motion Control

Beverage packaging operations face evolving demands that go beyond throughput—they require adaptable, user-friendly, and safety-conscious systems that consistently deliver accuracy under pressure. For manufacturers working with stand-up pouches, the challenge isn’t just producing more—it’s producing better. That means maintaining seal integrity, precise filling, clean labeling, and pouch consistency, even at top speeds.

Industrial Indexing Systems offers motion control solutions tailored to the rigorous needs of beverage packaging. Our technology empowers manufacturers to solve key production challenges with confidence—improving reliability, reducing waste, and enabling flexibility on the packaging line.

Here’s how our advanced motion systems support high-performance pouch packaging:

- Flexibility across formats – Rapid changeovers support a wide range of pouch sizes and materials. Whether switching between SKUs or adapting to different sealing types, the system stays responsive without sacrificing efficiency.

- Precision under pressure – Maintain consistent fill volumes, seal strength, and label alignment—even during high-speed production. Servo-controlled motion enables synchronized multi-axis control, reducing misalignment and seal defects.

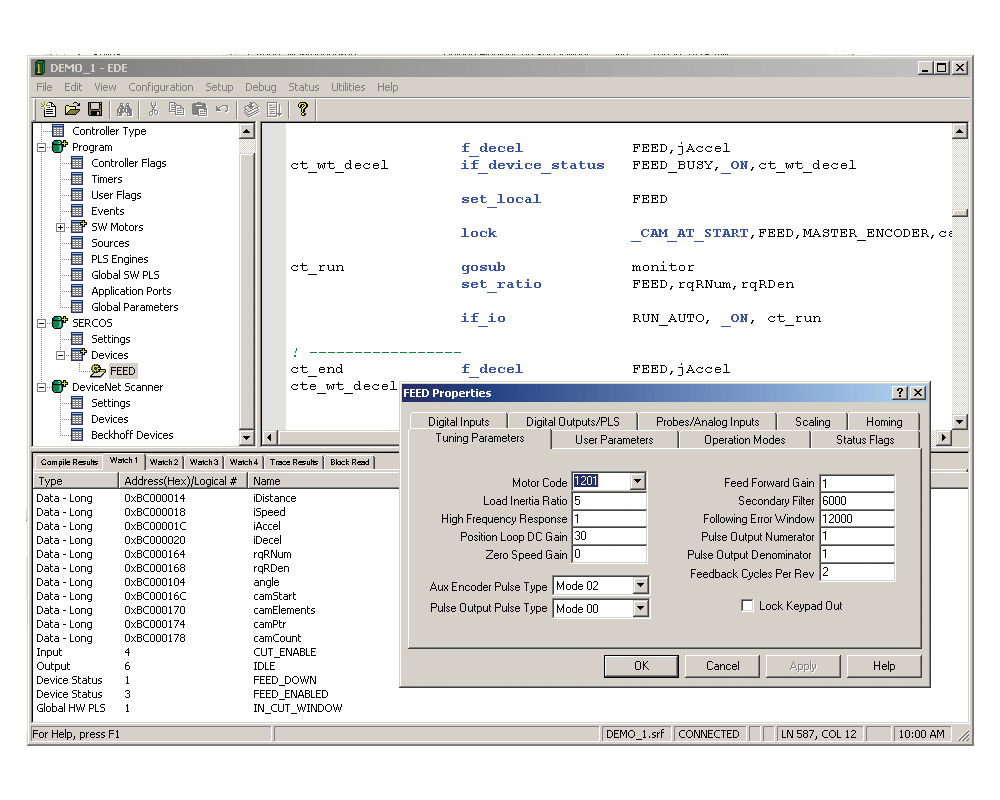

- Application-ready libraries – Hassle-free programming and reliable application libraries streamline your equipment operation with our user-friendly and intuitive programming interface.

- Operator-friendly design – An intuitive interface makes troubleshooting and system adjustments faster and more accessible, reducing downtime and reliance on specialized personnel.

- Built-in safety protocols – Enhanced safety features ensure worker protection during changeovers and maintenance, meeting modern industrial safety standards without compromising productivity.

- Expert support and service – From predictive maintenance tools to rapid replacement parts, access to experienced engineers ensures long-term operational stability and uptime.

These features collectively support the core priorities of pouch packaging: speed, precision, consistency, and safety. Whether you’re targeting faster cycle times, better seal quality, or tighter label placement, Industrial Indexing Systems delivers the control and confidence needed to meet today’s performance goals and tomorrow’s market expectations.

Future-Proof Your Packaging with Industrial Indexing Systems

With growing demand for stand-up pouch packaging, manufacturers must future-proof their packaging processes to stay competitive. Servo-driven automation is the key to ensuring high-speed production, precise motion control, and consistent product quality. By adopting advanced servo technology, companies can streamline operations, reduce downtime, and improve overall efficiency, allowing them to meet increasing market demands with confidence.

With growing demand for stand-up pouch packaging, manufacturers must future-proof their packaging processes to stay competitive. Servo-driven automation is the key to ensuring high-speed production, precise motion control, and consistent product quality. By adopting advanced servo technology, companies can streamline operations, reduce downtime, and improve overall efficiency, allowing them to meet increasing market demands with confidence.

At Industrial Indexing Systems, we provide servo motors, drives, and motion controllers for applications requiring high performance, high quality positioning accuracy, high reliability, and energy efficiency. With customizable configurations and precision control, our solutions help manufacturers enhance production flexibility, maintain strict quality standards, and drive long-term operational success.

Optimizing stand-up pouch packaging requires a balance of efficiency, precision, and quality control. Servo-driven automation ensures consistent sealing, precise filling, and accurate labeling while maintaining high-speed production. By reducing errors and material waste, manufacturers can improve efficiency, meet industry standards, and stay competitive in the growing flexible pouching market.

Take Your Packaging Operations to the Next Level

Don’t let inefficiencies hold back your production. Contact Industrial Indexing Systems to discover how our motion control solutions can optimize flexible pouching for beverage packaging.